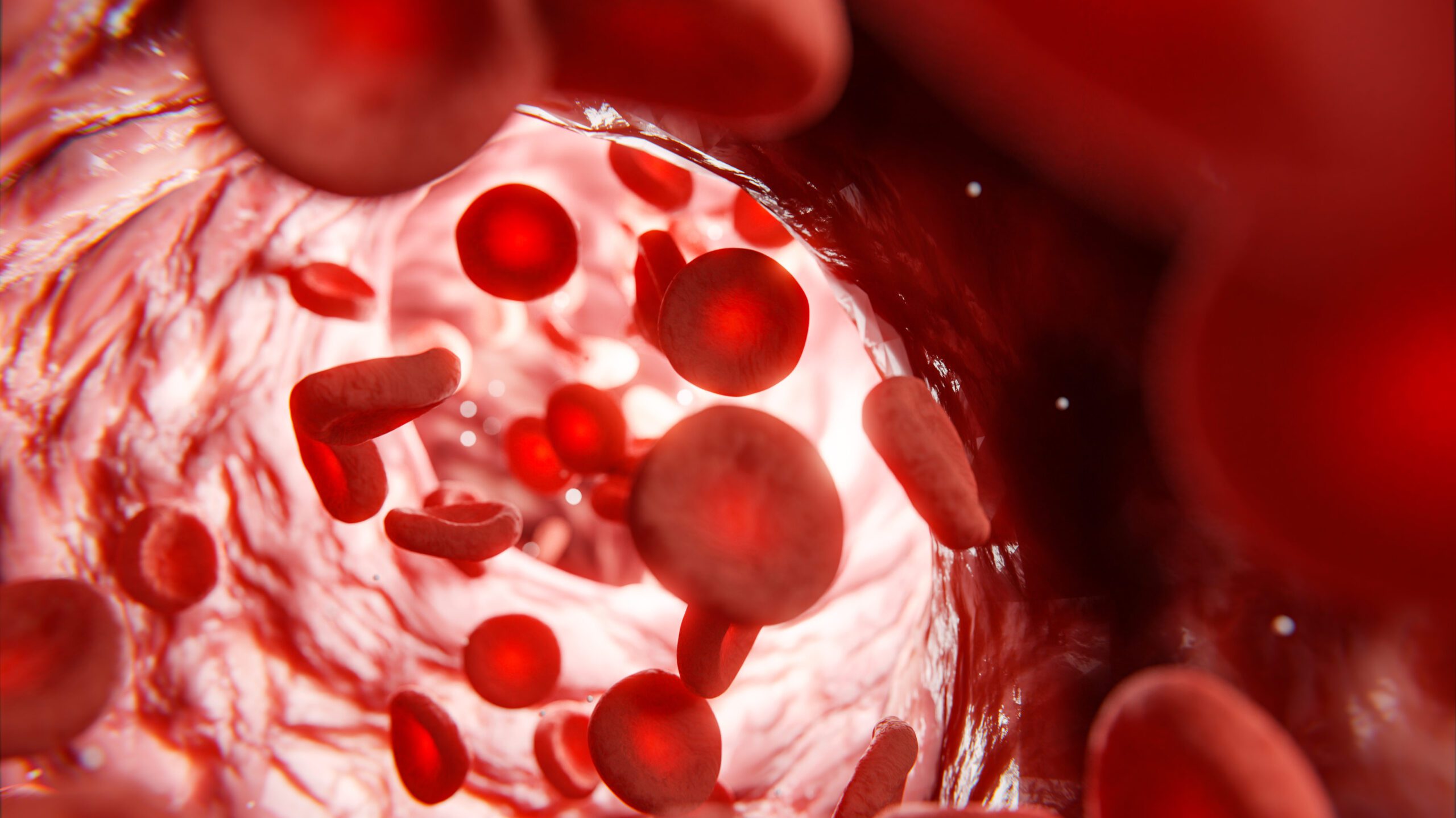

Theintegration of medical devices into the human circulatory system requires not just functional optimization but also biological synergy with host tissues. Endothelialization—the growth of endothelial cells on the device surface—is a critical determinant of biocompatibility and long-term device success. This cellular process not only mimics the natural vascular lining but also regulates essential functions such as hemostasis, immune modulation, and thrombosis prevention. Achieving rapid and uniform endothelialization can significantly improve clinical outcomes for devices such as vascular grafts, stents, and heart valves.

The Mechanistic Basis of Endothelialization

Endothelialization involves a complex sequence of cellular events beginning with the adhesion of endothelial progenitor cells (EPCs) to the device surface. These cells proliferate and differentiate, forming a monolayer of endothelial cells that mimic the natural endothelium. This layer plays a pivotal role in maintaining vascular homeostasis, largely through the production of bioactive molecules such as nitric oxide (NO), prostacyclin, and thrombomodulin.

The endothelial lining also acts as a barrier against thrombogenesis by suppressing platelet activation and coagulation cascade pathways. Furthermore, it regulates local inflammatory responses, ensuring the device integrates seamlessly with host tissues without eliciting chronic immune activation.

The biomechanical properties of the endothelial layer, particularly its ability to adapt to shear stress, are equally vital. This ensures the durability of the endothelial lining under the dynamic blood flow conditions experienced within the vascular system.

Challenges in Endothelialization of Medical Devices

The surfaces of many medical devices are inherently non-biological, posing challenges to cellular adhesion and proliferation. Key barriers include:

- Material Bio-inertness:

- Commonly used materials like stainless steel and certain polymers lack surface properties conducive to cellular attachment.

- Hydrophobic surfaces, in particular, repel proteins and cells necessary for initiating endothelialization.

- Geometry and Blood Flow Dynamics:

- Complex or irregular device geometries can disrupt laminar blood flow, creating areas of turbulence that impede endothelial cell migration.

- Inadequate flow-induced shear stress can hinder the alignment and stability of the endothelial layer.

- Biofouling:

- The deposition of proteins and other biological materials on device surfaces can lead to undesirable interactions, including platelet adhesion and bacterial colonization, which further obstruct endothelialization.

- Immune Response:

- Without a biocompatible surface, the device may trigger inflammatory cascades, leading to fibrosis or neointimal hyperplasia, which compromises long-term functionality.

Biomaterial Innovations to Enhance Endothelialization

The past decade has witnessed a surge in biomaterial engineering to overcome these challenges. Smart Reactors’ Camouflage™ coating represents a breakthrough in this field, leveraging advanced surface modification techniques to create a bioactive interface that promotes endothelialization. Camouflage™ is not a drug-eluting coating but rather a specialized surface technology designed to foster a natural biological response. Unlike drug-eluting systems, which rely on the release of bioactive agents, Camouflage™ works by creating an inert yet biologically optimized surface. Its unique design supports the adhesion and proliferation of endothelial cells without the need for pharmacological interventions. This minimizes potential side effects and ensures the coating maintains its structural integrity over time.

- Surface Bioactivity:

- Camouflage™ incorporates a proteinaceous base layer that mimics the extracellular matrix, providing the biochemical cues necessary for endothelial cell adhesion and proliferation.

- Micro- and Nanotexturing:

- The coating features micro- and nanoscale patterns designed to emulate the topography of natural tissue. This physical structure enhances cell attachment by promoting integrin-mediated adhesion.

- Hemocompatibility and Endothelial Cell Recruitment:

- Camouflage™ is optimized for hemocompatibility, minimizing platelet adhesion and activation. It also actively recruits EPCs to the surface, accelerating the formation of a functional endothelial layer.

Clinical Implications of Enhanced Endothelialization

The ability to achieve rapid and stable endothelialization is a defining factor in the success of various medical devices:

Vascular Stents:

Endothelialization reduces neointimal hyperplasia, a common cause of in-stent restenosis. The formation of an intact endothelial layer prevents smooth muscle proliferation and thrombosis, ensuring patency.

Heart Valves:

In valve replacements, endothelialization mimics the native endothelial covering, preventing leaflet calcification and thrombus formation. This is critical for long-term hemodynamic performance.

Vascular Grafts and Bypass Conduits:

Endothelialized grafts exhibit superior patency rates and reduced inflammatory complications compared to non-endothelialized alternatives.

Dialysis and Extracorporeal Circuits:

Devices that contact blood during extracorporeal procedures benefit from endothelialization as it minimizes biofouling and thrombogenesis.

The Role of Camouflage™ in Medical Device Innovation

Smart Reactors’ Camouflage™ coating exemplifies the convergence of biomaterial science and clinical need. By addressing the multifaceted challenges of endothelialization, this advanced coating enables medical devices to achieve superior integration with the body. Devices treated with Camouflage™ demonstrate reduced thrombogenicity, enhanced healing, and improved biocompatibility, ultimately leading to better patient outcomes.

The ability to combine micro- and nanostructured surfaces with biologically inert properties positions Camouflage™ as a game-changer in the field of implantable devices. Its versatility ensures applicability across a wide range of medical devices, from cardiovascular implants to extracorporeal systems, making it an indispensable tool for manufacturers seeking to elevate device performance.

Share this post: on LinkedIn