What is Thrombosis?

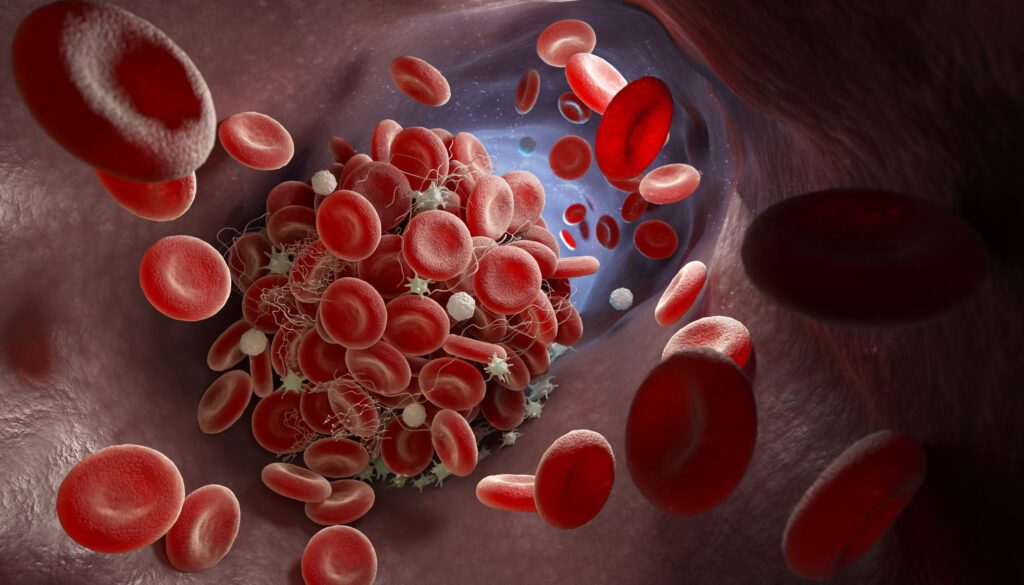

Thrombosis, the formation of a blood clot (thrombus) within a blood vessel, is a critical concern in medical device design, particularly for blood-contacting implants such as stents and flow diverters. The ability of a device to mitigate thrombosis is central to its safety and effectiveness. Smart Reactors’ Camouflage™ coating offers an innovative solution by addressing the underlying causes of thrombosis while enhancing the seamless integration of medical devices with the body.

Clinical Consequences of Thrombosis

Thrombosis occurs when a blood clot forms inside a blood vessel, obstructing blood flow. This disruption can lead to a range of serious clinical conditions. When a clot blocks a coronary artery, it can cause a heart attack, depriving heart tissue of oxygen.

Similarly, if a clot obstructs blood flow to the brain, it can trigger an ischemic stroke, leading to neurological impairments such as paralysis or cognitive defects. While blood clots form as a natural response to injury to prevent excessive bleeding, their formation in the wrong location can pose serious life-threatening risks. These outcomes highlight the critical need for effective prevention and management strategies in both clinical care and medical design.

Types of Thrombosis

- Arterial Thrombosis:

- Occurs in arteries carrying oxygen-rich blood from the heart. A clot can block blood flow to the heart or brain, potentially causing heart attacks or strokes.

- Venous Thrombosis:

- Occurs in veins that return oxygen-depleted blood to the heart. Deep vein thrombosis (DVT) is a common form, with the risk of pulmonary embolism if a clot travels to the lungs.

- Superficial Thrombosis:

- Clots that form near the skin and, while often painful, are typically less serious.

Challenges in Medical Device Design

Blood-contacting medical devices such as stents, vascular grafts, and flow diverters are prone to thrombus formation due to their foreign nature and interaction with blood components. Thrombosis on these devices can cause:

- Obstruction of Blood Flow:

- Thrombus formation can block blood vessels, compromising the device’s functionality.

- Device Failure:

- Thrombus-related inflammation can lead to restenosis or the narrowing of the treated vessel.

- Risk of Embolism:

- Pieces of the thrombus can detach and travel to other parts of the body, leading to severe complications like pulmonary embolism or stroke.

Key Players In Thrombosis

Thrombosis in medical devices is often driven by the following:

- Platelet Adhesion and Activation:

- Platelets adhere to the device surface and initiate clot formation.

- Coagulation Cascade:

- Activation of clotting factors leads to fibrin formation, stabilizing the clot.

- Inflammatory Response:

- The body’s immune response to foreign materials can exacerbate clot formation.

How Camouflage™ Coating: A Targeted Solution to Thrombosis

Smart Reactors’ Camouflage™ coating is specifically engineered to combat thrombosis and improve the safety and performance of medical devices. Its innovative design directly addresses the causes of thrombosis while promoting biocompatibility.

| 1. Non-Thrombogenic Surface | Camouflage™ minimizes platelet adhesion and activation by providing a smooth, hemocompatible surface. This reduces the likelihood of initiating the clotting cascade. |

| 2. Enhanced Endothelialization | By fostering the growth of endothelial cells, Camouflage™ creates a natural barrier that mimics the body’s own blood vessel lining. This reduces thrombogenicity and ensures better integration with the vascular system. |

| 3. Durability and Stability | Camouflage™ maintains its performance under the dynamic forces of blood flow, ensuring consistent protection against thrombus formation over time. |

| 4. Cytocompatibility | Camouflage™ is designed to support healthy cell proliferation while avoiding cytotoxic effects, ensuring that the coating preserves the integrity of surrounding tissue and the blood environment. |

Conclusion

Thrombosis presents a significant challenge in medical device design, with profound implications for both patient safety and device performance. Smart Reactors’ Camouflage™ coating offers a breakthrough solution by addressing the biological and mechanical factors that drive thrombogenesis. Through its hemocompatible, endothelialization-promoting properties, Camouflage™ not only prevents thrombosis but also enhances the integration and functionality of blood-contacting devices, setting a new standard for medical device coatings.

Share this post: on LinkedIn