Peritoneal dialysis (PD) is a life-changing treatment for patients with end-stage kidney disease (ESKD), offering a flexible, home-based alternative to traditional hemodialysis. By using the peritoneal membrane as a natural filter, PD removes toxins and excess fluids, enabling patients to maintain more independence in managing their condition. However, as with any medical treatment, challenges remain, particularly in ensuring the safety and efficiency of devices used in PD, such as catheters and tubing.

Scientific advancements, especially in surface coating technology, are paving the way for more reliable and effective solutions, addressing common complications in PD.

Understanding Challenges in Peritoneal Dialysis

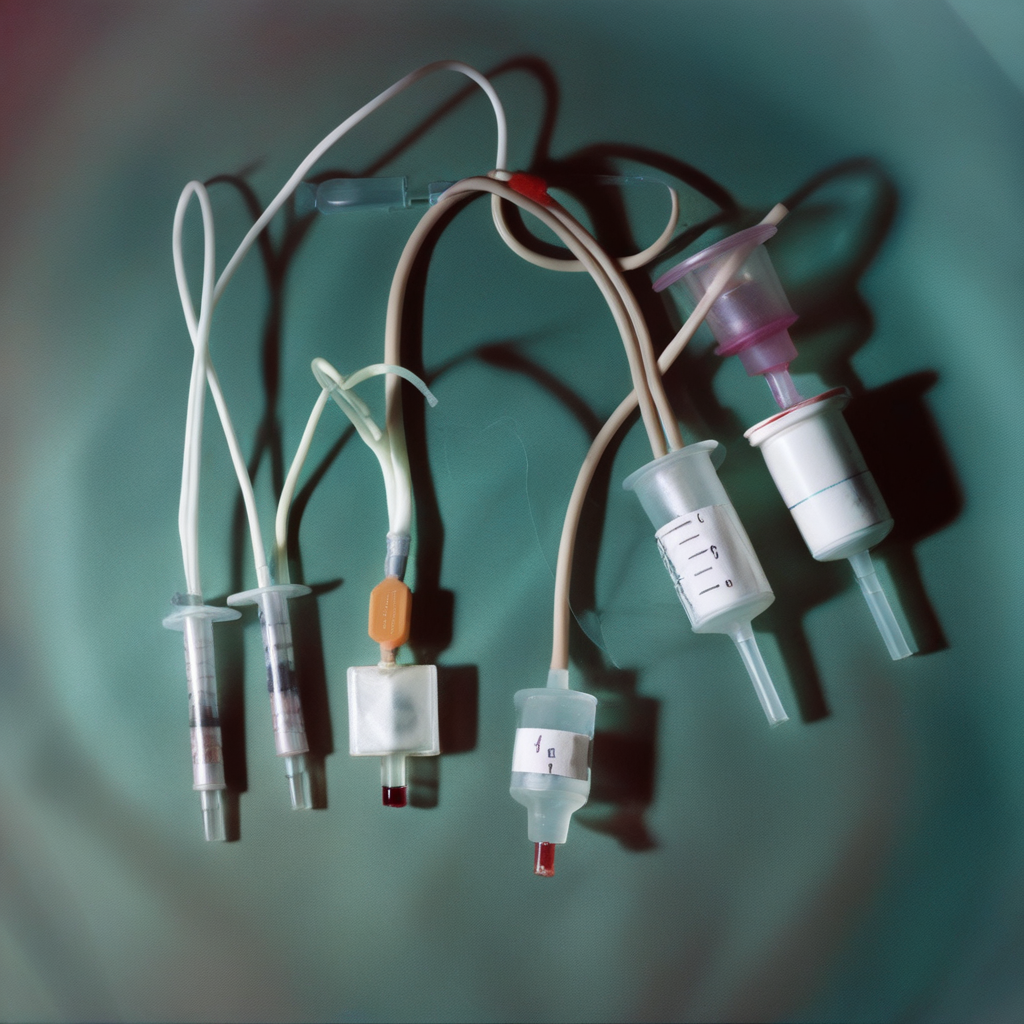

PD relies on medical devices to create a pathway for dialysate and facilitate the filtration process. These devices, while crucial, face several challenges when interacting with the peritoneal environment:

Infections and Biofouling: PD catheters can serve as a point of entry for bacteria, leading to infections such as peritonitis. Bacteria often form biofilms on catheter surfaces, making infections harder to treat and increasing the risk of complications.

Catheter Blockages: Over time, protein adsorption and tissue overgrowth can obstruct catheters, reducing their effectiveness and sometimes requiring surgical intervention.

Inflammatory Responses: The body’s natural reaction to foreign materials can cause irritation, inflammation, and even fibrosis, which may further complicate treatment.

These complications can impact not only the success of PD but also the quality of life for patients, highlighting the importance of innovative solutions.

The Role of Advanced Coatings in PD Devices

Advanced surface coatings are reshaping how PD devices function by enhancing their biocompatibility and longevity. By modifying the device surface at a molecular level, these coatings address several critical issues:

- Antimicrobial Protection: Preventing bacterial adhesion and biofilm formation helps reduce the risk of infections such as peritonitis. Antimicrobial coatings act as a protective barrier, stopping bacteria from colonizing device surfaces.

- Improved Biocompatibility: Coatings designed to mimic natural tissue properties reduce irritation and immune system activation. This improves the device’s interaction with the peritoneal environment and minimizes inflammation.

- Durable and Long-Lasting Performance: Advanced coatings protect device surfaces from wear and fouling, ensuring consistent functionality over time.

A Step Toward Safer Dialysis

Incorporating these advancements into PD devices not only addresses existing challenges but also opens the door to better patient outcomes. Patients benefit from fewer complications, reduced risk of infections, and a more comfortable treatment experience. For healthcare providers, these improvements translate into lower maintenance costs, fewer device replacements, and enhanced treatment reliability.

How Smart Reactors Supports Innovation in PD

At Smart Reactors, we are dedicated to developing solutions that enhance the safety and performance of medical devices. Our advanced coatings, including Camouflage™, embody this commitment by offering antimicrobial and biocompatible properties. Designed to integrate seamlessly with the body, Camouflage™ plays a subtle yet vital role in promoting safe and effective PD treatments.

PD remains a critical treatment option for many patients, but its long-term success depends on the performance of its devices. Advances in surface coatings are setting a new standard for safety, reliability, and comfort in dialysis care. At Smart Reactors, we are proud to contribute to this progress, working toward a future where PD is safer and more effective for everyone.

Share this post: on LinkedIn