Infections related to medical devices remain a significant challenge in healthcare, driving the need for advanced technologies to combat microbial contamination. At Smart Reactors, we are at the forefront of biocompatible innovation, ensuring that medical devices not only perform efficiently but also prioritize patient safety. Among our key advancements are biocidal coatings—engineered surfaces that actively fight against microbial threats and prevent biofilm formation.

What Are Biocidal Coatings?

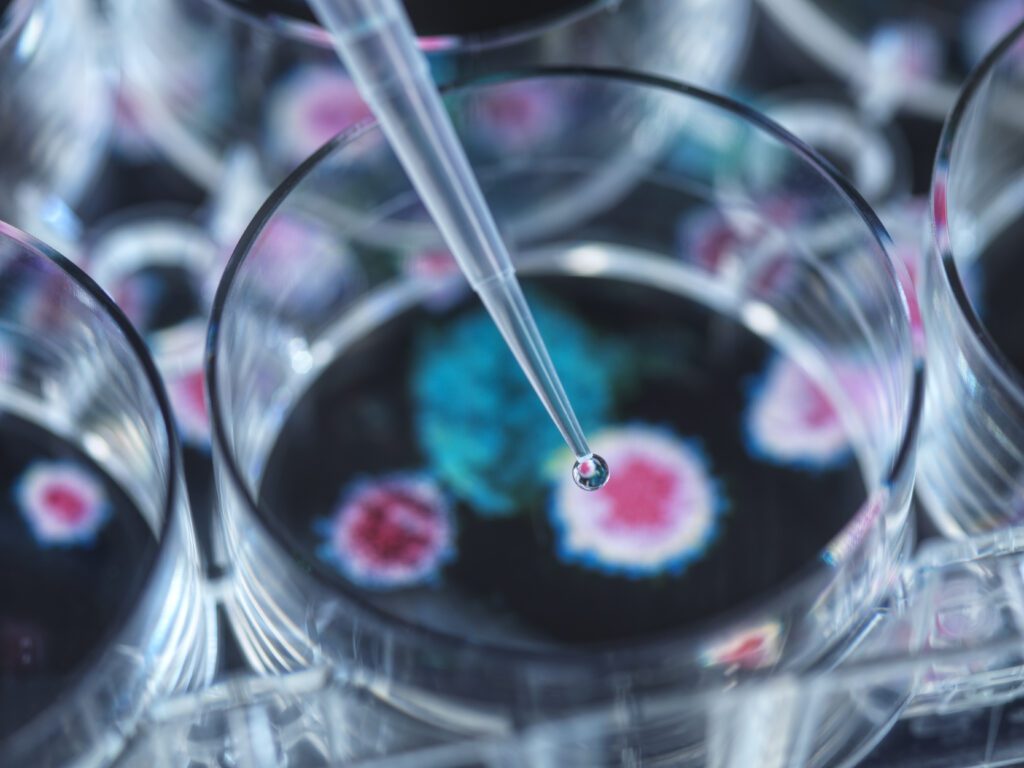

Biocidal coatings are specialized surfaces designed to eliminate or inhibit the growth of microorganisms. By integrating antimicrobial agents into the coating material, these solutions protect medical devices from contamination, improving safety and longevity. Unlike traditional antibiotics, biocidal coatings prevent microbial colonization without contributing to the development of antibiotic resistance.

Research has shown the potential of polycationic compounds like polyethyleneimine (PEI) and polydiallyldimethylammonium chloride (PDADMAC) as highly effective materials for biocidal coatings. These polymers exhibit unique electrostatic properties that allow them to interact directly with bacterial membranes, disrupting cell structure and function.

How Do Biocidal Coatings Work?

The effectiveness of biocidal coatings lies in their ability to interact with bacterial cells at a molecular level. The positively charged polycationic molecules in the coating are naturally attracted to the negatively charged membranes of bacteria. This interaction destabilizes the bacterial membrane, leading to the disruption of vital cellular processes and ultimately causing cell death.

Additionally, polycationic biocides such as PEI and PDADMAC have been shown to:

- Penetrate Bacterial Membranes: These molecules can enter bacterial cells, disrupting proteins and DNA, further ensuring microbial elimination.

- Prevent Biofilm Formation: By breaking down bacterial colonies before they can adhere to the surface, biocidal coatings reduce the risk of persistent infections.

- Offer Broad-Spectrum Protection: Effective against a wide range of pathogens, including antibiotic-resistant strains like Listeria monocytogenes, these coatings provide robust antimicrobial activity.

Key Benefits of Biocidal Coatings

- Enhanced Safety: Biocidal coatings significantly reduce the risk of healthcare-associated infections (HAIs), a leading concern in medical device usage.

- Durable Performance: The stability of these coatings ensures long-lasting protection, even under challenging environmental conditions.

- Resistance Mitigation: Unlike antibiotics, biocidal coatings do not contribute to bacterial resistance, making them a sustainable solution for infection control.

Applications in Medical Devices

The versatility of biocidal coatings makes them suitable for a wide range of medical applications. At Smart Reactors, we focus on integrating biocidal properties into coatings for devices such as:

Catheters and Implants: Reducing infection risks during and after implantation, improving patient outcomes.

Dialysis Membranes: Enhancing device performance by preventing biofilm formation and microbial contamination.

Extracorporeal Membrane Oxygenation (ECMO) Tubing: Maintaining efficiency in oxygenation and blood flow by mitigating biofouling.

Surgical Instruments: Ensuring sterile surfaces that minimize cross-contamination risks.

Our proprietary Camouflage™ coating technology combines antimicrobial efficacy with unmatched biocompatibility, making it the ideal solution for medical device manufacturers seeking to improve both safety and performance.

Why Choose Smart Reactors?

At Smart Reactors, we specialize in the development of advanced coatings that address the unique challenges faced by medical device manufacturers. Our Camouflage™ coating not only incorporates biocidal properties but also promotes natural healing through endothelialization and biocompatibility. By ensuring that medical devices integrate seamlessly into the body while resisting microbial threats, we offer solutions that prioritize both device performance and patient outcomes.

Our commitment to innovation extends beyond individual products. We work closely with our clients to provide end-to-end support, from prototyping to manufacturing, ensuring that every solution is tailored to meet their specific needs. Whether you are developing next-generation implants, vascular devices, or diagnostic tools, Smart Reactors is your partner in enhancing device safety and effectiveness.

Future Perspectives

The future of biocidal coatings lies in the integration of multifunctional properties, combining antimicrobial, anti-fouling, and biocompatible features. Advances in molecular engineering will enable the development of coatings that are more durable, sustainable, and effective. At Smart Reactors, we are committed to staying ahead of these trends, leveraging cutting-edge research to deliver solutions that redefine the standards of medical device safety.

Biocidal coatings represent a transformative advancement in medical device safety, offering a proactive solution to combat microbial contamination. By integrating these technologies into medical devices, Smart Reactors is not only enhancing product performance but also contributing to better patient care. With our expertise in biocompatible coatings and a dedication to innovation, we are proud to lead the way in creating safer, more effective healthcare solutions.

Share this post: on LinkedIn