The Critical Role of Chemotherapy Ports in Long-Term Treatment

Chemotherapy Implanted ports, also known as implantable ports or port-a-caths, are semi-implantable vascular access devices designed for patients requiring long-term intravenous therapy. Used primarily in chemotherapy, prolonged antibiotic treatment, and total parenteral nutrition (TPN), these devices provide a stable, repeatable access point for drug delivery while reducing the discomfort and complications associated with peripheral IVs.

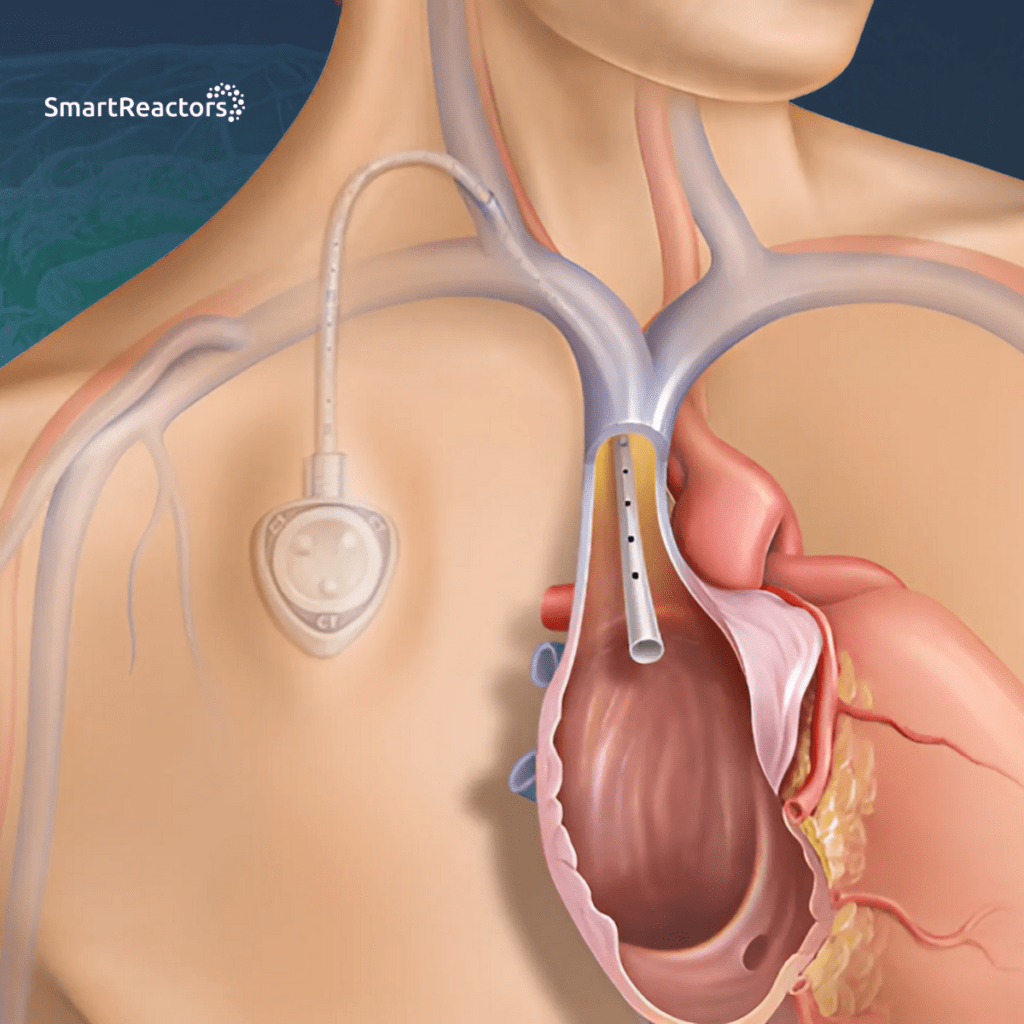

Each port consists of a small reservoir (port chamber) implanted under the skin, usually in the chest or upper arm, connected to a catheter that leads into a major vein. The device is accessed by inserting a Huber needle through the skin into a self-sealing silicone septum, allowing for multiple drug infusions, blood draws, and fluid administration over months or even years. Once treatment is complete, the port can be surgically removed.

While these devices improve patient comfort and treatment efficiency, their long-term performance depends on their ability to resist thrombosis, infection, and mechanical degradation. Addressing these challenges through advanced surface engineering is essential for improving patient outcomes.

Challenges in Chemotherapy Port Performance

One of the primary complications associated with chemotherapy ports is thrombosis. Over time, blood components can adhere to the catheter’s surface, leading to clot formation that obstructs the device. If thrombosis occurs at the catheter tip, it can block medication delivery and increase the risk of deep vein thrombosis (DVT). Maintaining a hemocompatible surface that prevents platelet adhesion is critical to ensuring the port remains functional for the duration of the treatment. Coatings that provide low-thrombogenic surfaces or controlled-release anticoagulant properties can help mitigate this risk.

Infection is another significant concern. Even though the port is implanted beneath the skin, bacteria can still enter through repeated needle punctures or travel along the catheter lumen. Catheter-related bloodstream infections (CRBSIs) are a leading cause of complications in vascular access devices, often due to biofilm formation on the internal surfaces. Once a biofilm develops, it becomes highly resistant to antibiotics, increasing the likelihood of sepsis or requiring port removal. Antimicrobial coatings that inhibit bacterial adhesion formation can help prevent these complications, reducing infection rates and improving device longevity.

Beyond clotting and infection risks, chemotherapy ports must also remain mechanically durable over time. Repeated needle punctures can weaken the silicone septum, causing leaks or compromising access. Additionally, prolonged implantation can lead to tissue irritation, fibrosis, or discomfort, affecting patient tolerance. Biocompatible surface modifications can minimize inflammatory responses and improve patient comfort, while reinforced polymer coatings can enhance septum durability, ensuring the device withstands thousands of punctures without degradation.

How Camouflage™ Coating Enhances Implanted Ports

Camouflage™ enhances the performance of implanted ports by addressing key challenges associated with their use. By improving the interaction between the device and the body, Camouflage™ increases fun

- Hemocompatibility Enhancement – Reduces platelet adhesion and clot formation, lowering the risk of thrombosis and ensuring long-term device patency.

- Antimicrobial Protection – Prevents bacterial colonization and biofilm development, reducing the risk of catheter-related bloodstream infections (CRBSIs).

- Biocompatibility for Long-Term Use – Minimizes inflammatory reactions and enhances patient comfort by ensuring a biologically inert surface.

- Reduced Surface Friction – Improves device interaction with surrounding tissue, reducing mechanical irritation and enhancing implant stability.

- Enhanced Longevity – By reducing friction, clotting, and inflammation, Camouflage™ can extend the longevity of the implanted port, reducing the need for replacement or repair.

Advancing Chemotherapy Port Technology with Smarter Surface Engineering

As vascular access devices become increasingly integral to long-term treatments, ensuring their biocompatibility, durability, and safety is paramount. Chemotherapy ports must provide consistent, reliable drug delivery while minimizing the risks of thrombosis, infection, and mechanical failure.

Through advanced surface modification, Smart Reactors is at the forefront of developing coatings that enhance device longevity, reduce complications, and improve patient outcomes.

For medical device manufacturers looking to optimize the next generation of chemotherapy ports, Camouflage™ offers a scientifically backed solution.

Contact us today to learn how Smart Reactors’ coating technology can enhance your vascular access devices.

Share this post: on LinkedIn