Heart valve replacements, essential in treating valvular heart diseases, face one significant challenge: thrombosis. The formation of blood clots on valve surfaces can compromise device functionality and pose life-threatening risks to patients. Antithrombotic coatings for heart valves have emerged as a breakthrough solution, minimizing clotting risks and enhancing the performance and safety of these vital implants.

Thrombosis: A Major Concern in Heart Valve Implants

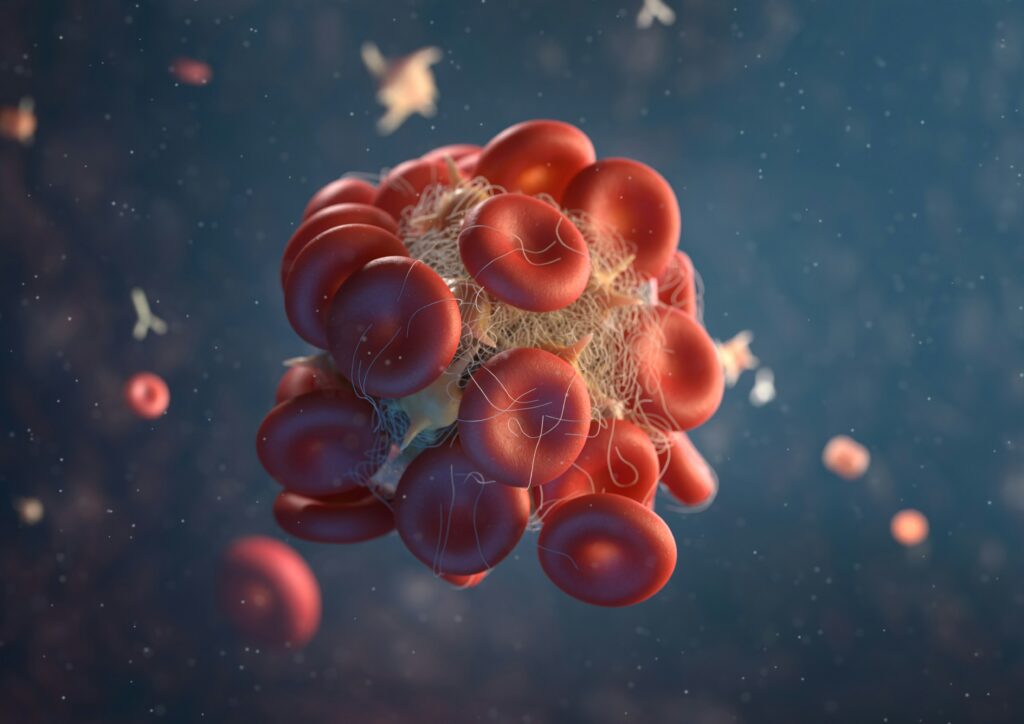

Thrombosis occurs when the interaction between blood and the artificial surfaces of heart valves triggers a cascade of biological responses. These include inflammatory protein adsorption, platelet activation, and the coagulation cascade, leading to thrombus formation. Left untreated, these clots can obstruct blood flow, damage the valve, or result in severe complications such as stroke.

Mechanical Valves: Known for their durability, these valves are constructed from materials like titanium and cobalt-chromium alloys. Despite their mechanical advantages, their surfaces are prone to triggering thrombosis without adequate surface modifications.

Bioprosthetic Valves: While more biologically compatible due to their tissue-based construction, these valves are still susceptible to clot formation and calcification over time, impacting their long-term performance.

Systemic anticoagulation therapy, the current standard to mitigate thrombosis, comes with significant drawbacks, including bleeding risks and reduced patient quality of life. This underscores the critical role of surface modifications like antithrombotic coatings in improving hemocompatibility and reducing complications.

The Role of Antithrombotic Coatings for Heart Valves

Antithrombotic coatings work by modifying the surface properties of heart valves to prevent clot formation at its source. These coatings combine advanced materials and bioengineering techniques to create surfaces that resist protein adsorption and platelet activation while promoting natural compatibility with blood.

| Novel Passive Surface Modifications: | Inorganic Coatings: Materials such as diamond-like carbon (DLC) and titanium oxide (TiO₂) provide smooth, low-energy surfaces that inhibit platelet adhesion. DLC is particularly effective due to its chemical inertness and mechanical stability. Superhydrophilic Polymers: Hydrophilic coatings create hydration barriers, preventing the initial protein adhesion that triggers clot formation. |

| Bioactive Coatings: | Coatings infused with anticoagulants (e.g., heparin) and fibrinolytic agents actively prevent thrombosis by disrupting the coagulation cascade directly at the valve surface |

| Endothelialization-Promoting Coatings: | These coatings encourage the growth of endothelial cells, recreating the natural lining of blood vessels and reducing long-term clotting risks. |

| Nano-Textured Surfaces: | Nano-scale textures reduce turbulence and create a pseudo-neointimal layer, stabilizing the interaction between the valve and blood to minimize thrombus formation. |

Smart Reactors’ Camouflage™ Coating: Leading the Way in Antithrombotic Innovation

Smart Reactors’ Camouflage™ coating leverages cutting-edge technology to redefine the performance of heart valve implants. Designed with a focus on antithrombosis, Camouflage™ integrates several advanced features:

- Thrombosis Resistance: Minimizes clotting risks through controlled protein absorption

- Enhanced Hemocompatibility: Reduces platelet adhesion and protein adsorption, ensuring safer, long-term blood interaction.

- Endothelialization Support: Facilitates natural cell growth to form a protective, biocompatible layer over the valve surface.

- Durability and Performance: Provides exceptional wear resistance, which is critical for the demanding environment of the cardiovascular system.

The adoption of antithrombotic coatings for heart valves is revolutionizing the management of thrombosis in cardiac implants. By reducing clotting risks, these coatings not only improve the safety and efficacy of heart valve replacements but also enhance patient quality of life by minimizing reliance on anticoagulation therapies.Smart Reactors is at the forefront of this innovation with its Camouflage™ coating, a solution designed to set new standards in heart valve performance. Contact us today to learn more about how Camouflage™ can transform your cardiac devices.

Share this post: on LinkedIn