What are Venous Stents and Flow Diverters?

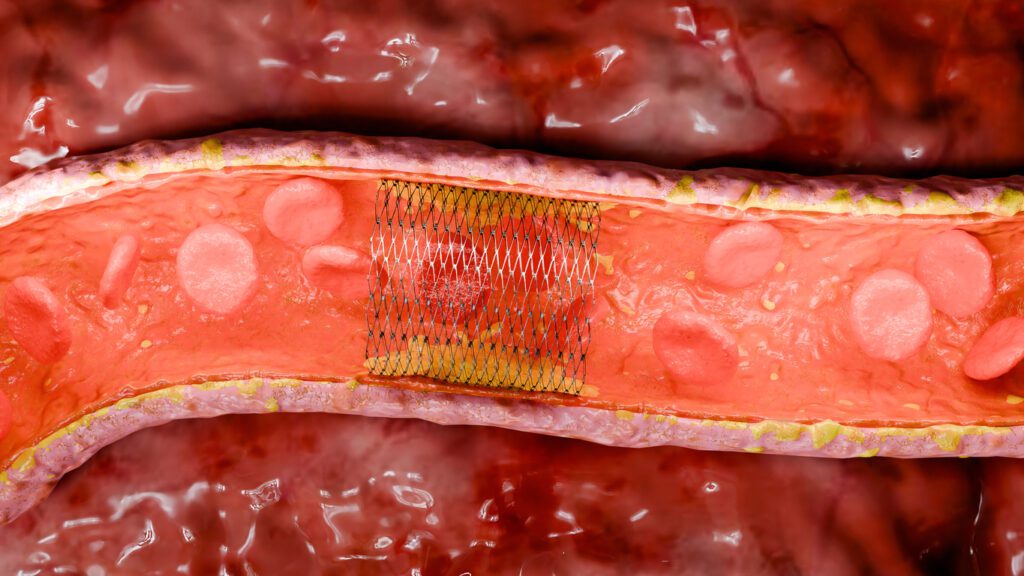

Stents are medical devices which support weakened or narrowed blood vessels restoring blood flow. Initially developed to address coronary artery disease, stents can now be used for a variety of different applications including peripheral artery disease, cerebrovascular disease and they even have non-vascular applications. They are of critical importance to the medical device industry as they restore blood flow to the heart or other affected areas. This prevents heart attacks, strokes and other complications as keeping blood vessels open ensures that organs receive an adequate blood supply preventing damage or dysfunction.

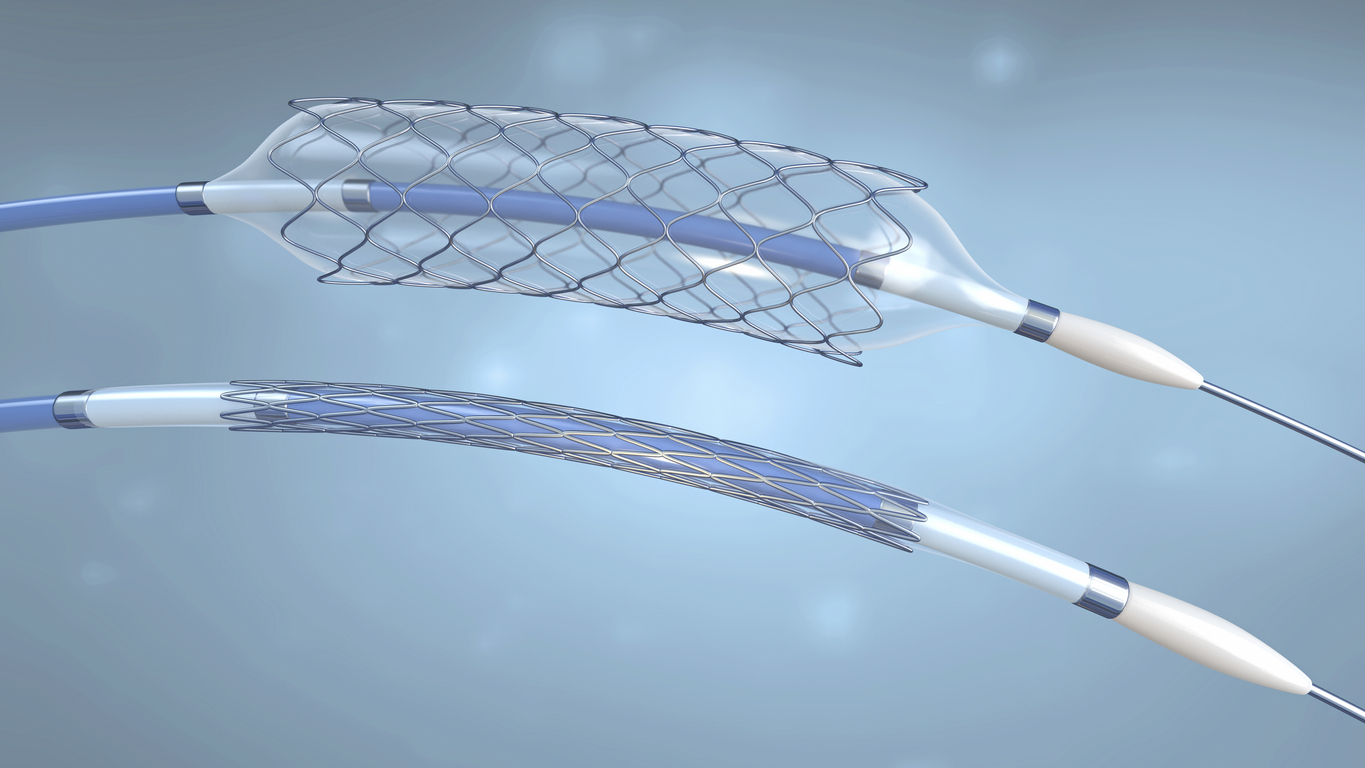

Flow diverters are specialised medical devices primarily used in the treatment of large or complex brain aneurysms. They work by diverting blood away from the aneurysm, encouraging flow along the natural path of the blood vessel. This reduces the risk of aneurysm rupture which could lead to a haemorrhagic stroke. Flow diverters have a cylindrical mesh-like structure which are specifically designed to alter the flow of blood within the vessel.

This is achieved by placing the device at the neck of the aneurysm within the affected vessel. The dense mesh structure of the flow diverter slows down the flow of blood to the aneurysm while maintaining circulation within the vessel. This reduced blood flow induces thrombus formation within the aneurysm sealing it off. Over time the vessel wall begins to heal and strengthen. Flow diverters are important devices as they reduce the need for open brain surgery thus providing a less invasive alternative.

Procedure for Stent and Flow Diverter Placement

The procedure involved in placing a stent or flow diverter is minimally invasive compared to the surgical alternatives. In preparation, the patient receives either a general or local anaesthetic depending on the type of procedure being done. A catheter is inserted into a large artery in the groin or arm to allow for the stent or flow diverter to be inserted.

Using fluoroscopy the device is guided to the desired location. Prior to this procedure the stent is crimped to reduce the size of the device to allow ease of access through the patient’s vascular system.

When the stent is positioned in the desired location a small ballon is used to expand the stent allowing it to support and open the affected vessels. Alternatively a self-expanding stent is used which doesn’t require a balloon catheter.

Post procedure patients may need to stay in hospital for observation, but this would be for a much shorter period of time than what is required for other more invasive surgeries. In many cases patients use dual anti-platelet therapy which helps prevent thrombus formation. Concerns about patient adherence to such medication are a primary driver to use hemocompatible coating technology on such devices to reduce the risk of thrombus formation.

Common Materials used in Stent & Flow Diverter Manufacturing

Stents and flow diverters can be made from a variety of materials including metal alloys, polymers or a combination of materials. In general, however, the main materials used when fabricating stents and flow diverters are nitinol and cobalt chromium.

Nitinol is a metal alloy composed with near equal parts nickel and titanium. This material is used in the field of medical devices due to its super elastic properties making it up to 10 times more flexible than other metals as well as its thermal shape memory properties. This shape memory effect describes a metal that can undergo a reversible phase transformation between Austenite and Martensite. Under high temperatures nitinol enters the Austenite phase. In this phase it achieves maximum stiffness and is spring like when bent. Nitinol is then in its Martensite phase during low temperatures. In this phase, the metal feels rubbery and bends easily.

When nitinol is in its Martensite state, it can easily deform into a new shape. However, when heated through its transformation temperature, it reverts to Austenite and returns to its previous shape.

Slight changes in the alloy composition or heat treatment effects the temperature at which nitinol remembers its high-temperature form.

The specific application for the device determines the optimal transition temperature. In the case of stents, a transition temperature close to or equal to human body temperature is selected allowing the stent to revert to its original shape post crimping.

Cobalt chromium is another commonly used material for stents but is mainly used in flow diverter manufacturing. This is due to its high corrosion resistance and biocompatibility which reduces complications with surrounding tissue, when implanted. It is also a chemically inert material which minimizes the possibility of irritation, allergic reaction and immune response. Cobalt chromium is also an extremely strong alloy allowing for thinner struts while maintaining radial strength.

Stent Material Selection – Need for Hemocompatible Coatings

There are a variety of risks associated with stents and flow diverters including stent restenosis, which is the narrowing of the stent area after treatment (in arterial vessels), and the risk of blood clot formation. While the materials used for stents and flow diverters do have a natural level of biocompatibility it is not high enough to prevent thrombus formation and thus risking health complications for the patient. It is recommended that blood thinning medication is taken to minimises clot initiation & cascade.

With arterial stents the primary clinical complication is restenosis. Drug eluting coatings are used to reduce potential restenosis. However for stents placed in the venous system or for neurovascular flow diverters, thrombosis presents a much bigger risk.

Drug eluting stents help prevent restenosis by using a thin coating which delivers medication directly to the bloodstream and the arterial walls. This inhibits cell proliferation to mitigate cell growth through the spaces between struts. Consequently, this disrupts endothelisation of the stent surface and reendothelisation of the vessel walls. The resulting consequence is a slow down of the healing of the vessel wall as well as preventing long term hemocompatibility and the risk of thrombus formation further down the line. There are also a variety of complications associated with long term exposure to the medications used in drug eluting stents. Drug eluting coatings are not considered to be a desirable solution in the venous or neurovasculature system as restenosis is not the major cause of clinical failure.

Another, more favourable method for the prevention of thrombus formation is through the use of hemocompatible coatings such as Smart Reactors CamouflageTM Coating Technology.

There are many factors to be considered when selecting an appropriate hemocompatible coating for the use with stents & flow diverters. Firstly, the coating must improve the hemocompatibility of the device surface preventing the coagulation cascade. The coating must also be highly durable both to blood flow and high mechanical force.

Another, more favourable method for the prevention of thrombus formation is through the use of hemocompatible coatings such as Smart Reactors CamouflageTM Coating Technology.

There are many factors to be considered when selecting an appropriate hemocompatible coating for the use with stents & flow diverters.Firstly, the coating must improve the hemocompatibility of the device surface preventing the coagulation cascade. The coating must also be highly durable both to blood flow and high mechanical force. As previously discussed, a stent undergoes crimping for deployment, so it is important that the coating is not damaged by this process. Finally, the coating must promote endothelisation on the surface of the stent or flow diverter. This will allow for long term hemocompatibility significantly reducing the risk

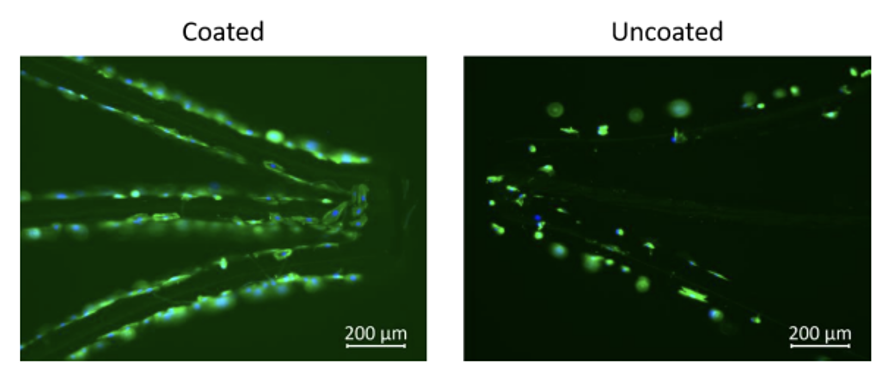

of thrombus formation. All of this can be achieved with Smart Reactors CamouflageTM which has demonstrates excellent hemocompatibility, long term durability and promotes the endothelisation process. Figure 4 illustrates the growth of endothelial cells on the surface of a CamouflageTMcoated stent, when compared to an uncoated control. Further benefits of Smart ReactorsCamouflageTM coating is that is possess all of the desired characteristics listed above without the use of any pharmaceuticals, therefore patients are not exposed to medication long term,unlike drug eluting stents.

Methods for testing Hemocompatible Coatings for Stents and Flow Diverters

When determining an appropriate hemocompatible coating for a stent or flow diverter it is important to understand the methods used to evaluate the coating. Firstly, it is vital to ascertain whether or not the applied coating improves the hemocompatibility of the device surface. There are a variety of methods used, however the most widely used is the Chandler Loop system.

This works by placing a coated stent or flow diverter inside a closed loop of PVC tubing filled with human blood. This is then rotated to allow the blood to interact with the device surface while in flow. Post-testing, the blood is analysed for biomarkers which indicate the activation of the coagulation cascade. Based on the detected biomarkers the level of hemocompatibility can be determined. Smart Reactors CamouflageTM coating has been shown to improve the hemocompatibility of stents and flow diverters through Chandler Loop testing.

Methods for evaluating Endothelisation properties on Stents and Flow Diverters

As previously discussed, it is important that a coating promotes endothelisation on the surface of a stent or flow diverter. This can be determined through static cell culturing techniques. In this method the coated stent or flow diverter is placed in a cell culture medium alongside Human Umbilical Vein Endothelial Cells (HUVECs) and left for a period of time ranging from 1-14 days. Once the culture period has been reached cell adhesion to the device surface is determined through fluorescent microscopy or scanning electron microscopy (SEM).

Figure 4 shows the endothelial cell adhesion of a Smart Reactors CamouflageTM coated stent compared to an uncoated stent through fluorescent microscopy. This image clearly shows how Smart Reactors CamouflageTM promotes significant growth of endothelial cells on the surface of a stent. Following on from this the cytotoxic effects of the coating are evaluated. This verifies that the cells which have grown on the surface of the coated stent or flow diverter are alive and healthy. This is achieved using cytotoxicity assays and cell counting. Once again Smart Reactors CamouflageTM has been shown not to have a cytotoxic effect on endothelial cells.

Conclusion

Stents and Flow Diverters are crucial in the medical device industry providing lifesaving treatment with minimally invasive procedures. Stents help support weakened or blocked blood vessels while flow diverters are crucial in the management of complex brain aneurysms. However, with all blood contacting medical devices there is a risk of thrombus formation due to poor material hemocompatibility. That is why the use of hemocompatible coatings such as Smart Reactors CamouflageTM coating is of vital importance to help reduce the risk of blood clot formation improving the long term hemocompatibility of Stents and Flow Diverters.

Share this post: on LinkedIn